|

|

|

|

|

|

|

MAXIMUM VERSATILITY AND

PERFORMANCE

|

|

|

|

|

|

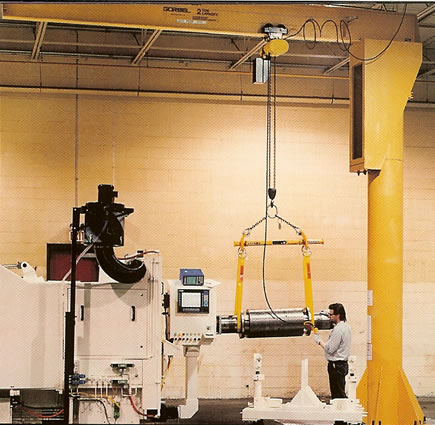

*Our most versatile

crane. Perfect for

underneath traveling cranes, in open

areas where it can serve several work

stations, in outdoor applications such

as loading docks, or in machining and

assembly operations where it can be

overlapped with other jibs to provide

staged operation.

|

|

|

|

|

|

EASE

OF OPERATION |

|

|

|

|

|

|

*Allows operators

to position loads

precisely, effortlessly and efficiently.

|

|

*Precision

tapered roller bearings in top

pivot and trunnion assemblies provide

smooth operation and long life. |

|

*Full

supporting triangular base plate

gussets are used (in lieu of struts) to

minimize crane deflection, thus

making it easier to accurately position

loads. |

|

|

|

|

|

SAFETY |

|

|

|

|

Available

in insert mounted (FS350) and sleeve insert mounted

(FS350S) styles |

|

|

|

|

|

*Head

retaining pin provides the

resistance to accidental upward

dislodgment of the head.

|

|

|

|

|

*Pre-engineered

for use with powered

hoists. A factor of 15% of the jib crane

capacity is allowed for the hoist and

trolley weight with an additional 25%

of the capacity allowed for impact,

thus giving maximum capacity use of

the jib. |

Pricing

and Dimensional Specifications -

Click a Load Capacity Link Here |

|

|

|

|

|

|

|

|

|

|

|

POWER ROTATION |

|

|

Is Optional |

|

|

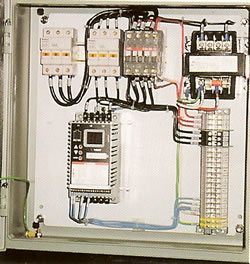

| FEATURES

OF MOTORIZED CONTROL PACKAGE |

|

|

|

|

|

|

|

|

|

•

Variable Frequency Drive (VFD) is standard. |

|

|

|

The

Variable Frequency Drive can be used in single or multiple speed

applications. |

|

|

|

|

|

|

|

•

Variable Frequency Drive provides the ultimate in load control. |

|

|

|

The

VFD provides the ultimate in load control and positioning from the

slowest possible creep speed up to maximum speed. The VFD is up to

25 times smoother than ballast resistor controls, does not produce

extensive heat, and enables precise starting and stopping. |

|

|

|

|

|

|

|

•

Easily adjustable speed control. |

|

|

|

Through

a simple keypad on the VFD, the acceleration rate,

deceleration rate and rotation speed can be adjusted to fit your application.

This allows you to customize the performance of the jib to your exact

requirements. |

|

|

|

|

|

|

|

•

Designed for indoor and outdoor use. |

|

|

|

When

being used outdoors, the cranes are designed to operate in

winds of 15 mph or less, based on a maximum load surface of 16 square

feet. Consult us for applications exceeding these standards. |

The

direct drive powers the rotation

of the Free Standing Crane. A speed

of 1/2 RPM is standard. |

|

|

|

|

|

|

|

•

Standard NEMA 4X Controls Enclosure. |

|

|

|

|

|

|

Standard

controls enclosure meets the requirements for NEMA 3R,

12, 4 and 4X environments. Optional enclosures are available for other

environments. |

|

|

|

|

|

•

Low maintenance costs. |

|

|

The

VFD eliminates the need for magnetic reversing contractors,

reduces the number of wearable components in the panel, and reduces

long-term maintenance costs. |

|

|

|

|

|

Pricing

and Dimensional Specifications -

Click a Load Capacity Link Here |

|

|

|

Variable

Speed Controls provide the

ultimate in jib crane rotation control form

creep speed to maximum speed. |

|

|

|

|

|

| STEP

4 - HEAD INSTALLATION |

| TIP:

Trunnion rollers should have full face contact with mast pipe when properly

installed. |

|

|

|

4.1

Wipe protective grease coating off

and/or remove tape from pivot pin. |

|

|

|

|

4.2

Place and orient tapered roller bearing

inner race (cone) on the mast pivot pin

(diagram 4A). |

|

4.3

Remove safety channel from head

assembly if it is bolted into place. |

|

4.4

Place the head on the mast. Install V-ring seal

(shipped loose) over mast pivot pin and press against

weight bearing frame. Secure head by inserting the

safety retaining pin into the hole located in the

mast pivot pin. Ensure that the safety retaining pin

is centered to within 1/16” inside of the mast pivot

pin. Place 2 hose clamps (one on either side) over

each end of the safety retaining pin and slide them

inward until they come in contact with the mast

pivot pin (diagram 4B). Tighten both hose clamps

such that the safety retaining pin is locked into

place without the ability to slide sideways. Also

ensure that both hose clamps are identically

oriented on the pin and, once tightened, ensure the

clamp screws are facing downward. |

|

|

|

|

Note: It

is imperative that the safety retaining pin

is installed in the “centered” position to avoid a

possible interference with the threaded stud welded

to the weight bearing frame. |

|

|

|

4.5 Reinstall

the safety channel into the head if removed

in step 4.3. |

|

|